L&T Group Websites

- Corporate

- Corporate – Arabic

- CarbonLite Solutions

- GreenTech

- Heavy Engineering

- Hydrocarbon

- LTIMindtree

- L&T Construction

- L&T Construction & Mining Machinery

- L&T Finance

- L&T Howden

- L&T Hydraulics

- L&T Infrastructure Finance Company Limited

- L&T Institute of Project Management

- L&T Technology Services

- L&T Kuwait Construction

- L&T MBDA Missile Systems Limited

- L&T Metro Rail (Hyderabad) Limited

- L&T-MHI Power Boilers

- L&T-MHI Power Turbine Generators

- L&T Precision Engineering and Systems

- L&T Realty

- L&T-Sargent & Lundy Limited

- L&T Special Steels and Heavy Forgings

- L&T-SuFin

- L&T Valves Limited

- Nabha Power Limited

- L&T Public Charitable Trust

- Rubber Processing Machinery

- Shipbuilding

- L&T Skill Trainers Academy

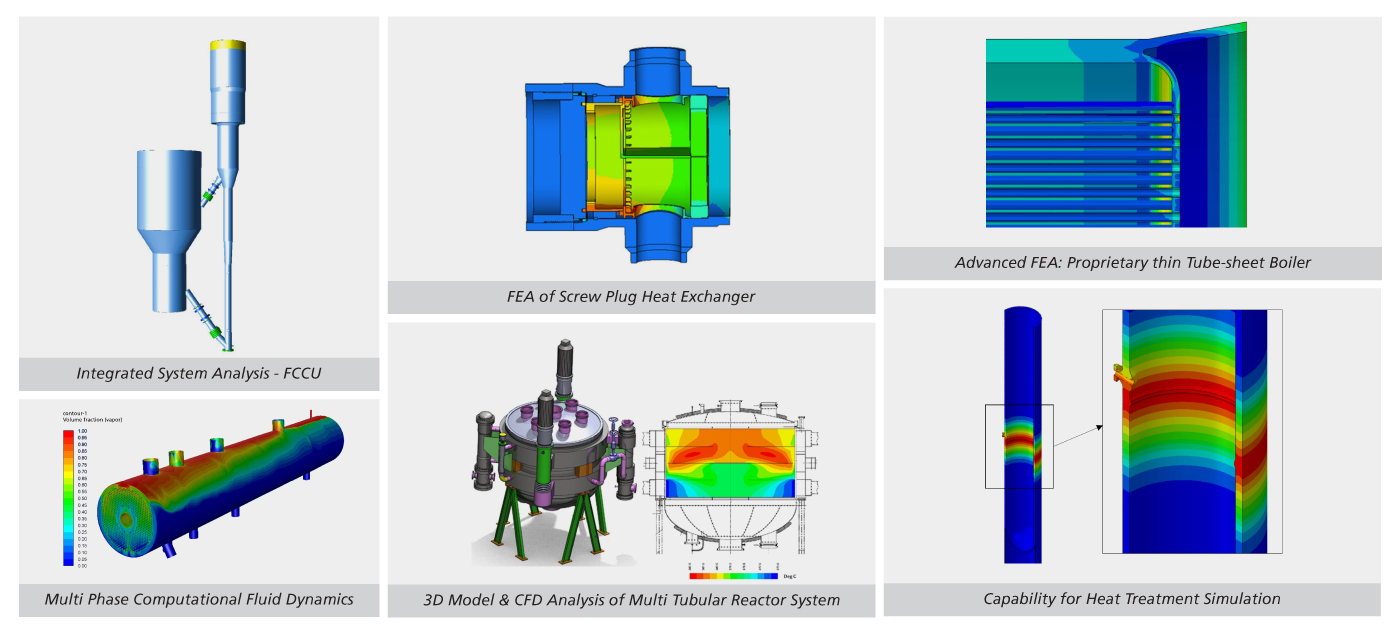

Design & Engineering

L&T’s engineering capabilities are geared to design equipment as per customer specific requirements, and international codes and standards. Fabrication drawings for critical equipment are generated through 3D automation which have been developed in house.

The perpetual endeavour of design engineers is to generate optimum solutions leading to lowest capital and operating costs.

Technology Solution from a Single Source

| Mechanical | Thermal |

|---|---|

|

|

| Analysis | Special |

|

|